Accusize Industrial Tools 5-1/2” 5C Collet Chuck with Integral D1-5 Camlock Mounting, 3/4” Stud, 0269-0015

£451.00

Description

Price: $451.00

(as of Jun 05, 2025 23:23:14 UTC – Details)

Product Description

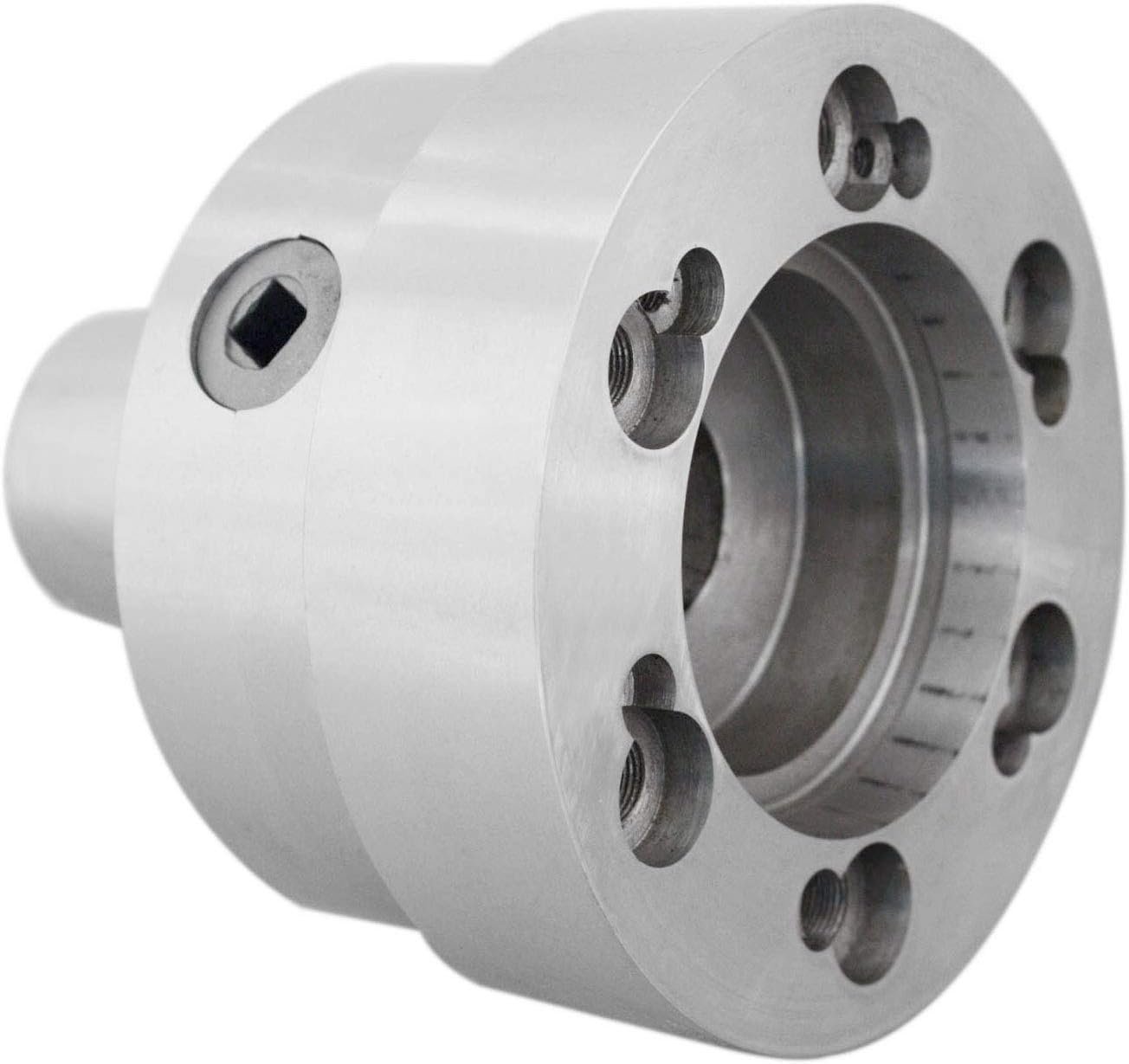

AccusizeTools – 5C, 5″ Collet Chuck with Integral D1-5 Camlock Mounting, 0269-0015

Please don’t buy this item unless you are familiar with this type of product. Thanks.Outside diameter: 5-1/2″Spindle: D1-5 cam lockNo. of stud: 6Diameter of stud: 3/4″Integrated D1-5 back mounting. Install on the machine in seconds, no machining requiredCan be used on any lathe with D1-5 cam lock mountingCustomers don’t need to do any work when received, just mount it on your machine spindle and go.Can use any size 5C collet Round collet: 1/16 ~ 1-1/8″; Hex collet: 1/8″ ~ 7/8″;Square Collet: 1/8″ ~ 3/4″Scroll and pinion design just like 3-jaw chuck , operated with chuck key.Scroll & pinion precision machined and hardenedMax. RPM 6000TIR: 0.0006″

Note

Please note that you need to confirm the taper of your lathe using this 5C collet chuck is 14°15′ before you place an order. Otherwise, the run-out will not be accurate at all. Please don’t buy the chuck unless the taper of your lathe is exactly 14°15′. Usually, when a lathe has been running for a few years, its taper becomes not as accurate as a new lathe, which causes inaccurate run-out when operating the 5C collet chuck.

The method of measuring the 0269-5C Collet Chucks: Step 1

Check the runout of lathe spindle first. Adjust the runout value of nose within 0.004mm; of cylinder or taper within 0.004mm shown as left.

The method of measuring the 0269-5C Collet Chucks: Step 2

Then put the 5C chuck onto the lathe spindle nose, with the setting hole at the right position to fix each other (While measuring, we used the screw lock device shown in picture-1. We did not have cam lock device shown in picture-2. They work theoretically the same, by different methods.)

The method of measuring the 0269-5C Collet Chucks: Step 3 and Step 4

After putting the 5C fixture into the measuring equipment, enable the screw lock or the cam lock to work with the chuck on the measuring equipment. Please be noticed to tighten the cam screws in multiple strokes crossly.Approach the surface of the taper hole with a micron indicator; then rotate the measuring equipment slightly. Reading and noting the micrometer’s value. Tighten the one or two cam screws to correct the 5C fixture, until the runout value within 0.006mm.

The method of measuring the 0269-5C Collet Chucks: Step 5

Applying the standard 5C measuring bar, use two lock gears to tighten it slightly. And assure the run-out of the 5C fixture orifice, 0.015mm.

Add to Cart

Add to Cart

Customer Reviews

2.8 out of 5 stars 23

4.5 out of 5 stars 8

Price

$451.00$451.00 $393.00$393.00

Outside Diameter

5-1/2″ 5″

Installation

Work with D1-5 cam lock Requires a backplate adapter

Collet Size

Round: 1/16″ – 1-1/8″, Hex: 1/8″ – 7/8″, Square: 1/8″ – 3/4″ Round: 1/16″ – 1-1/8″, Hex: 1/8″ – 7/8″, Square: 1/8″ – 3/4″

Max. RPM

6000 RPM 6000 RPM

Total Indicator Reading (TIR)

0.0006″ 0.0006″

SKU #

0269-0015 0269-0010

5C 5-1/2″ Collet Chuck with Integral D1-5 Camlock Mounting, Stud = 5/8″, #0269-0015

Outside diameter: 5-1/2″

Spindle: D1-5 cam lock

No. of stud: 6

Diameter of stud: 3/4″

Precision Integration: Directly fits lathe machines with D1-5 camlock mounts; no additional machining needed for installation.

Versatile Collet Compatibility: Accommodates 5C collets from 1/16″ to 1-1/8″ (round), 1/8″ to 7/8″ (hex), and 1/8″ to 3/4″ (square), broadening workpiece versatility.

Effortless Setup: Features an integrated D1-5 back mounting for quick, effortless setup, ensuring immediate use upon receipt.

High-Speed Operation: Designed for maximum speeds up to 6000 RPM, supporting efficient machining operations.

Exceptional Precision: Offers a total indicator reading (TIR) of 0.0006″, ensuring high precision for critical applications.

Customers say

Customers find the collet chuck looks great and offers good value for money, with one customer noting it’s really impressive for its inexpensive price point. The quality receives mixed feedback.

Reviews

There are no reviews yet.